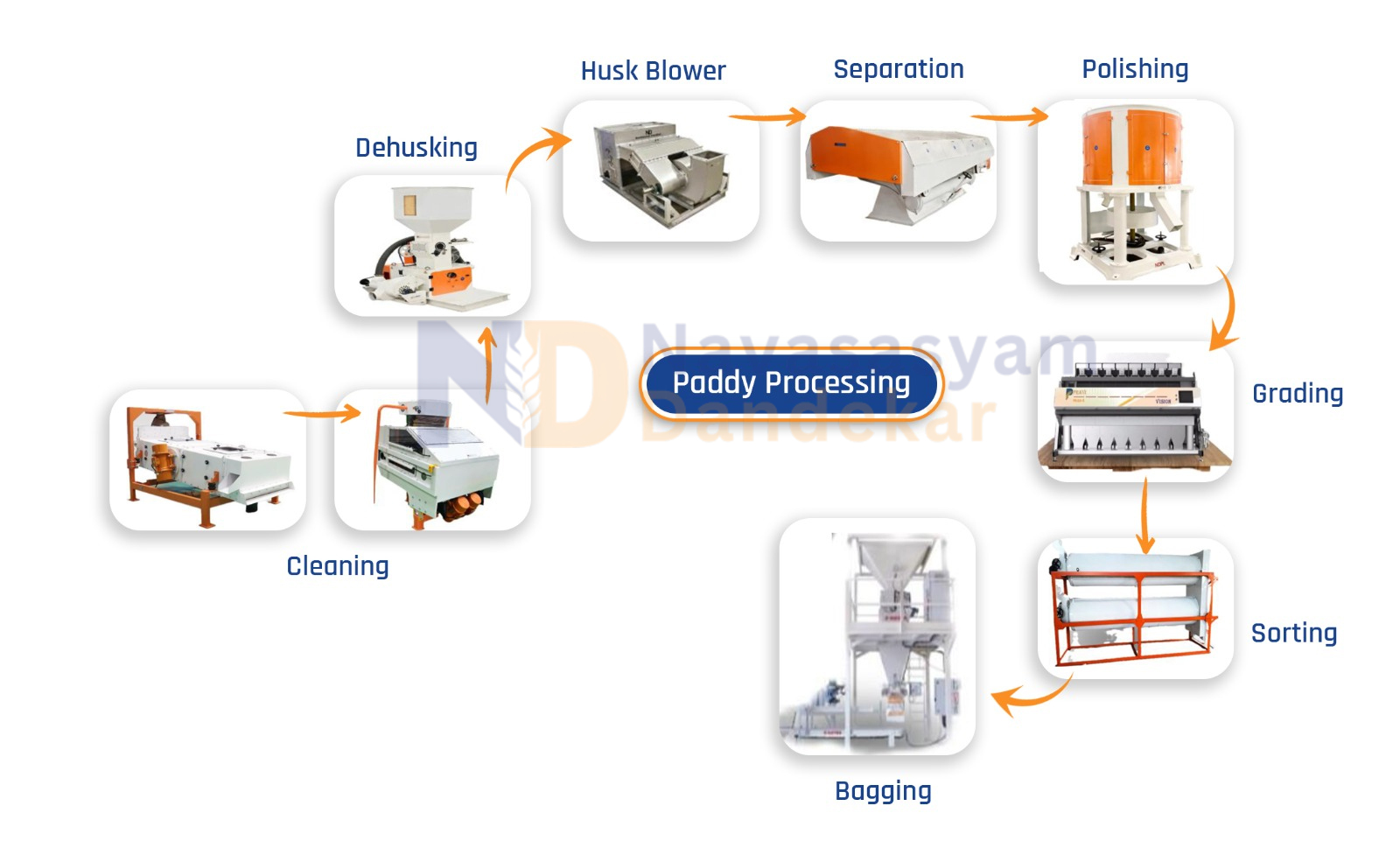

The paddy milling process is the method of converting harvested paddy rice (unhusked rice) into white rice that is suitable for consumption.It involves several stages to remove the outer layers of the grain (husk and bran) while minimizing damage to the rice kernel.

Dehusking (Husking)

Removes the husk (outer shell) from the paddy.

Produces brown rice (rice with bran layers still intact).

Husk is often removed using a rubber roller or sheller (PNU)

Whitening (Polishing)

Removes the bran layer from brown rice to produce white rice.

Can involve several machines for better polish and appearance.

Often done in 3-4 steps for better quality by using Cone Polishers or Whiteners.

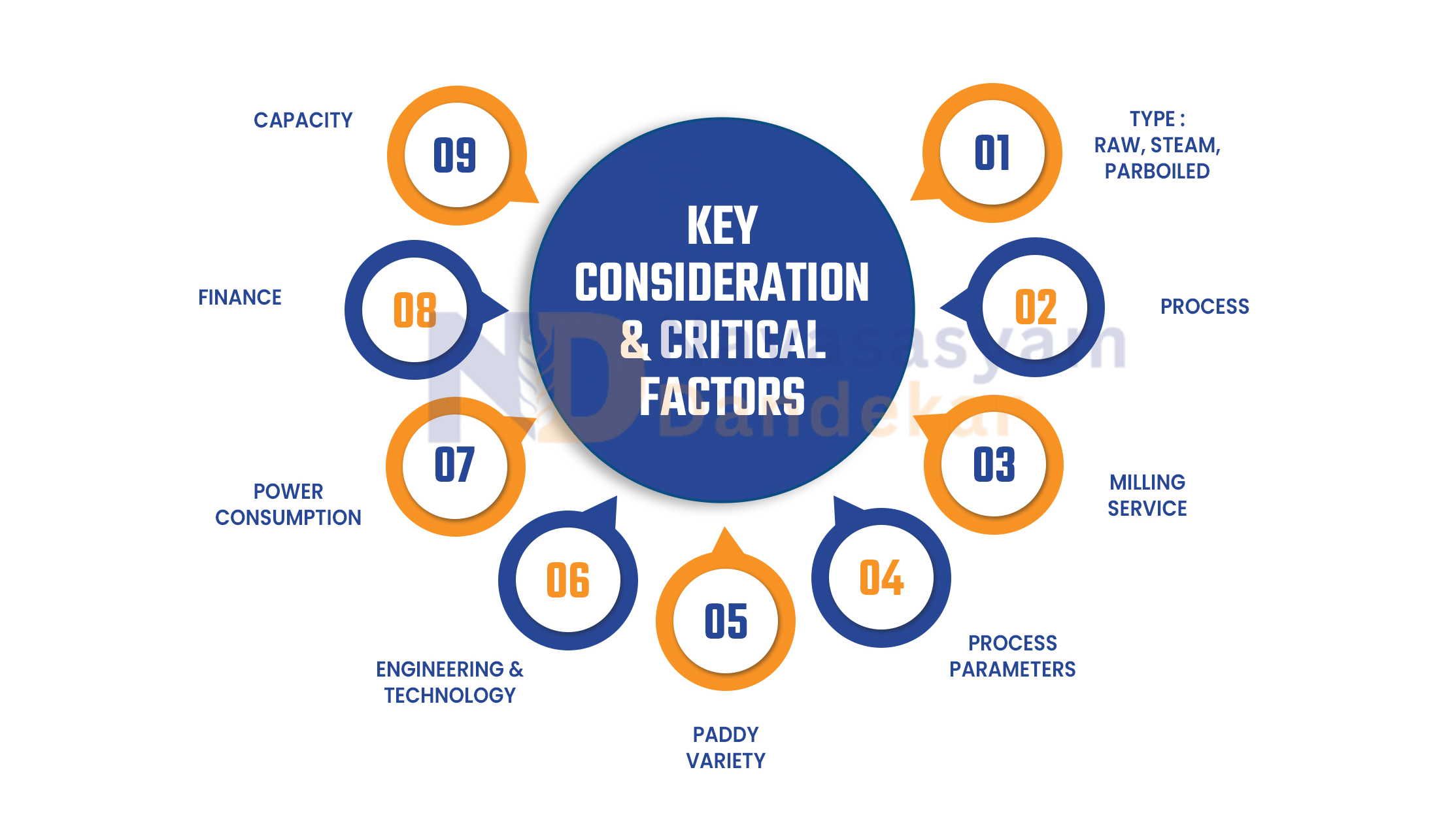

Raw rice is directly milled from the paddy.

Steaming: After soaking, the rice is steamed. During steaming, the rice paddy is exposed to high-temperature steam, which completes the gelatinization process. This step ensures that the rice becomes more transparent and firmer. Drying: Once steamed, the rice is dried to reduce its moisture content.

Parboiling is a hydrothermal treatment in which paddy is soaked in water and steamed to obtain gelatinized rice. Parboiling seals any cracks within the rice, causing the rice to become harder and resulting in a higher milling yield with less breakage.

Basmati and Non Basmati Rice Producing States

| Rice Type | States |

|---|---|

| Non Basmati Rice Producing States | Haryana, Punjab, Uttar Pradesh, Jharkhand, Bihar, West Bengal, Orissa, Assam, Karnataka, Andhra Pradesh, Telangana, Tamil Nadu and Maharashtra, Madhya Pradesh, Chhattisgarh |

| Basmati Rice Producing States | Punjab, Haryana, Western UP, Uttaranchal, Himachal Pradesh |

Rice milling is the process of removing the husk and bran layer to produce white rice. Rice milling can be undertaken as:

A multistage process where rice passes through a number of different operations and machines from paddy to white rice.

We Study under the different section for multistage milling process.

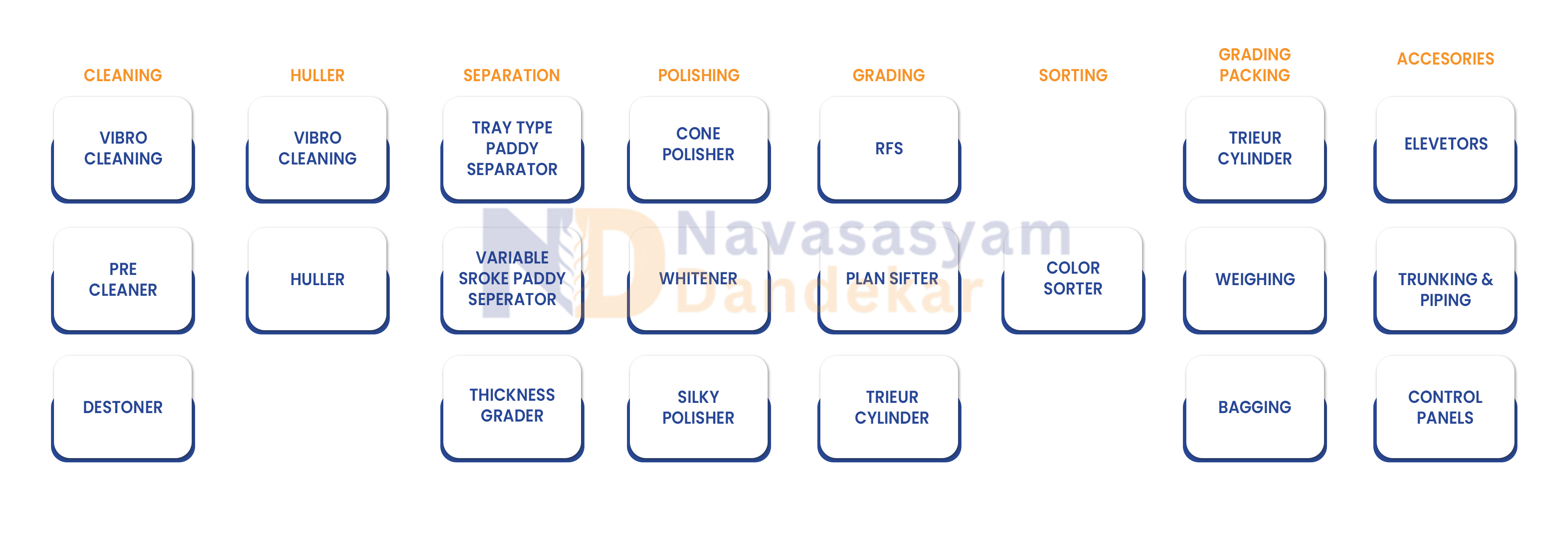

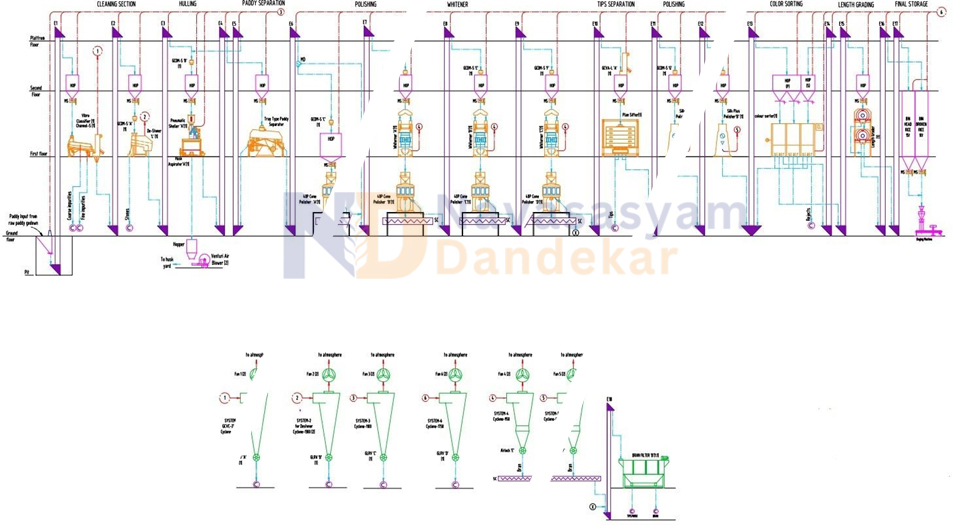

The milling process in larger commercial mills combines a number of operations that produces higher quality and higher yields of white rice from paddy or rough rice. The process involves:

| Intake / Pre-Cleaning section | Removing farm and other foreign impurities like sand, straw etc. Removing Stones, Gravity separation, weevil etc. |

| Fine Cleaning Section | Removes lighter impurities such as dust, dirt, chaff straw & stones by blowing or sucking air through the mass of falling grain and removing these light impurities in the air stream. |

| Hulling Section | Removing the husk or outer layer from the paddy. |

| Separation Section | Uses the difference in specific gravity and the buoyancy to separate paddy and brown rice. |

| Polishing Section | The Brown Rice to removing the bran layer and the germ. |

| Grading Section | Separated into head rice and, large and small broken rice by a sifter. |

| Waterjet Polishing Section | Using water gives the output grain a shiny surface, thus the name “silky” polisher. |

| Sorting & Grading Section | Shape & Colour Sorting. & Grading as per size. |

| Bagging Section | Packaging of white Rice according to requirement. |

| Germ/Bran/Husk | Managing the by-products. |

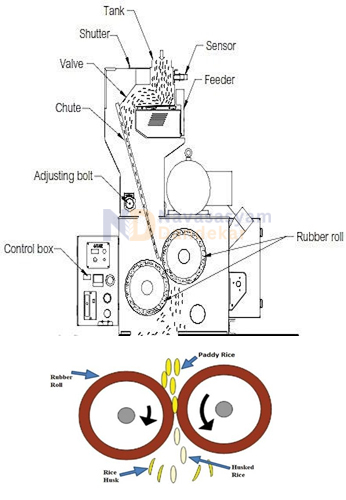

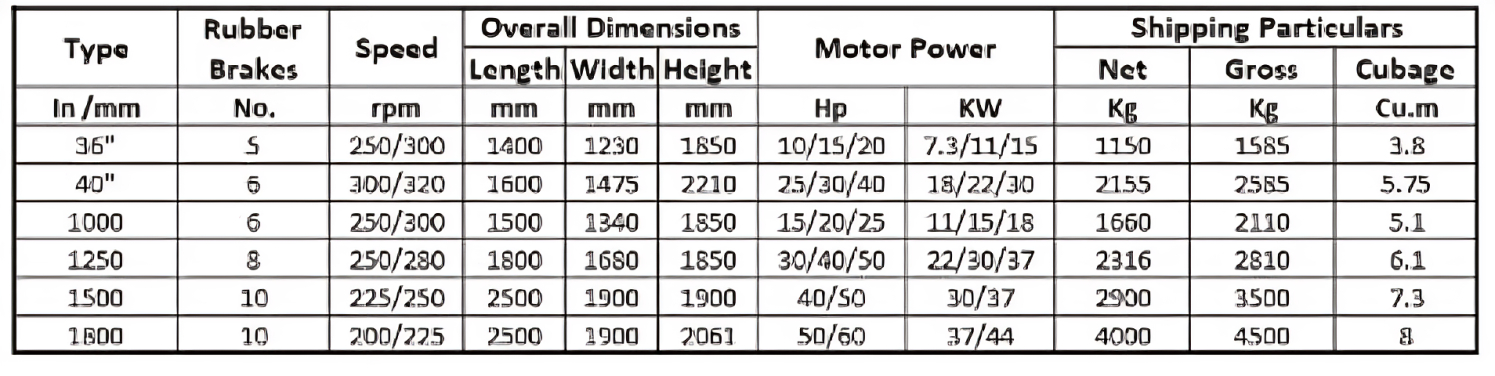

Pneumatic Rubber Roll Sheller

The Rubber-roller Sheller is the most efficient hulling machine. As the name suggests two rubber rollers of the same diameter are operated at different speeds to remove the husk from the paddy. One roller has a fixed position and the other is adjustable to meet the desired clearance.

The adjustable roller rotates slightly slower than the fixed roller. Rubber-roll hullers have an aspirator in the base of the machine to separate the hulls from the brown rice.

The roll diameter varies from 250 to 300 mm and the roller width from 250 to 300 mm. The correct clearance is dependent on the varietal characteristics and the width and length of paddy.

This method of hulling can achieve hulling efficiencies of 90% to 95% with minimum broken or cracked grain.

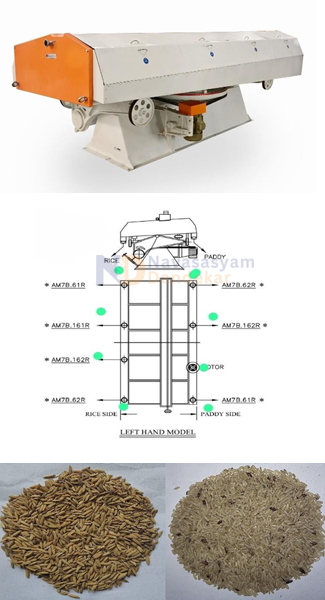

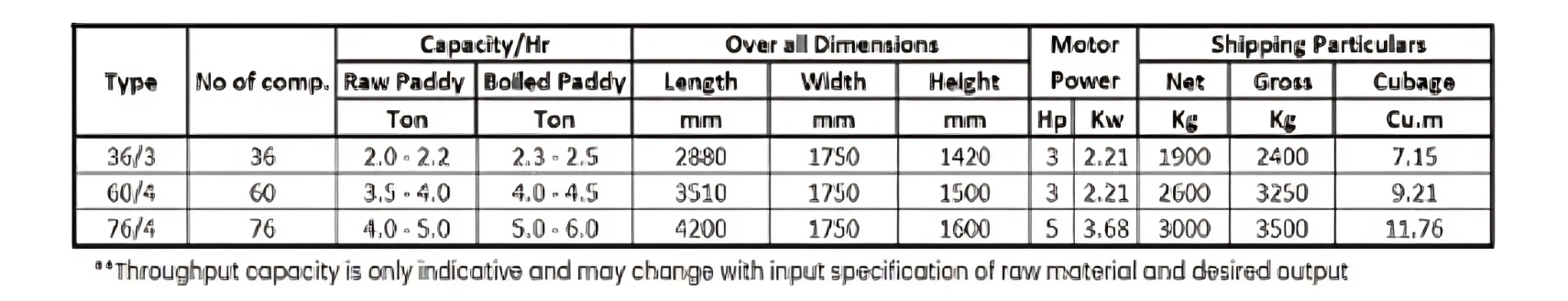

Paddy Separator

Application:

To separate paddy grains from brown rice by exploiting differences in surface texture and density, ensuring high purity and efficiency in the milling process. Primarily works on the principle of specific gravity.

By spreading the mixtures of unhusked and husked paddy to be separated over an Inclined surface, the grains constituting the mixture are subject to intermittent obliquely upward thrusts and in this process the rice slides down and the paddy moves up the two fractions of the mixture are collected at the opposite sides of sloping surface because of their movement in the opposite direction.

Advantages:

- Low power consumption.

- 100% separation of brown rice from unshelled paddy.

- Stroke adjustability depending on variety of paddy.

- Output increases by 10% for S.S. Flooring Sheet & Zig-Zags.

- Complete separation results in saving an additional elevator and power.

Salient Features:

- Stainless Steel + metal body construction.

- Lower cost of operation and maintenance.

- Sturdiness & durability.

- Trouble free performance.

Pearling Cone Polisher

Application:

For Buffing or Polishing the rice kernels to change their appearance, tase and texture. It transforms brown rice into white rice by removing the brown bran layer, ensuring maximum recovery with minimum brokens.

The whitening process is generally accomplished in 3 or 4 passes depending on the capacity, requirement and application. Construction consists of a Heavy-Duty Cast-Iron base, Middle Plate and Top Ring as the structural frame, an Abrasive Polishing Stone, an Ammeter, a Feeding Hopper, a Discharge outlet, a Drive Motor, and a Pressure Control Mechanism.

Advantages and Features:

- better stability of machine.

- Suitable to process Boiled and Steam Rice.

- Lesser cake formation and choking of bran due to larger screen area.

- Recovery of entire bran reduces dependency on Silky Machine, resulting in huge power savings.

- Unique tapered design and bigger polishing surface area results in uniform polish of every rice kernel.

- Minimum power consumption for Bran Aspiration System.

- Available in Vitrified Abrasive Stone and manual coated Cone assembly.

- Ammeter measures the ongoing current in the circuit, helps in monitoring the power.

- Vitrified Abrasive Stone ensures minimum brokens, reduces rubber brakes consumption and saves electricity.

Whitener (VJT) Polisher

Application:

Rice Whitener incorporates advanced techniques to whiten brown rice. The product is subjected to abrasion in the whitening chamber between the sieves and grinding wheels to remove a thin layer of bran. To attain the desired whiteness, the rice is subject to additional passes in the whiteners. It uses the vertical abrasive grinding wheel that follows the top to bottom working principle.

The rice is whitened very gently between grinding wheel & screen without changing the original shape of the rice kernel. It is constructed with silicon carbide wheels to reduce the grain damage during the whitening process. A specially designed aspiration system removes the bran produced during the whitening process.

Advantages and Features:

- Vertically mounted silicon carbide grinding wheels assures higher head rice yield and reduce broken yield.

- Differential manometer for precise control of chamber air pressure.

- Ensures uniform whiteness on all grains.

- Silicon carbide grinding wheels.

- Adjustable CNC punched sieves.

- Spring controlled whitening adjustment.

- Stainless steel discharge.

- Exhaust connection for bran suction.

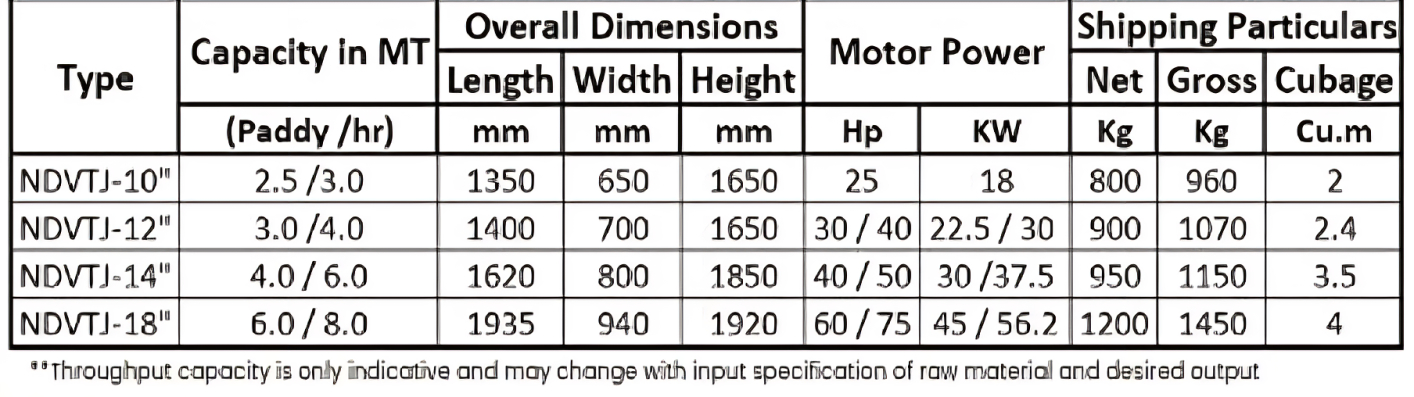

- Available Range - 2 TPH to 8 TPH

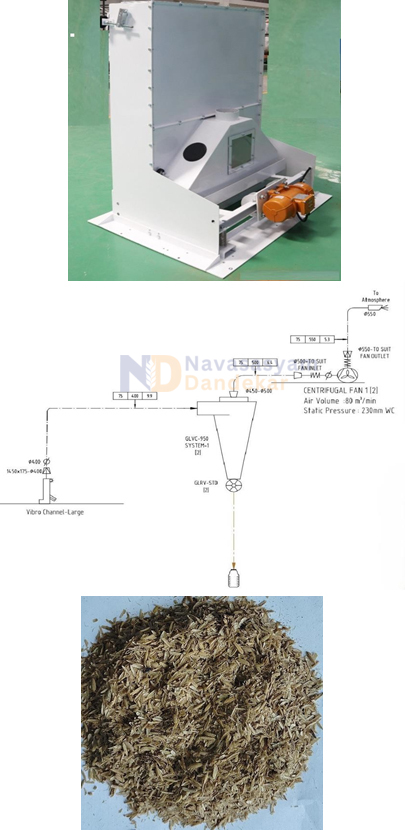

Vibro Aspiration Column

Product Description:

The Vibro Aspiration Column is a high-efficiency solution designed for the effective cleaning and grading of grains. This machine ensures the removal of light impurities, dust, husk, and other contaminants, resulting in superior grain quality.

Key Features:

- Efficient Aspiration System

- Vibratory Action

- Adjustable Air Flow

- High Capacity

- Robust Construction

- User-Friendly Design

- Energy Efficient

Application:

- Grain Processing Plants

- Rice Mills

- Seed Cleaning Operations

- Flour Mills

- Agricultural Product Processing

Advantages:

- Superior Grain Quality: Ensures removal of dust, husk, and other light impurities, enhancing the overall quality of the grain.

- Versatility: Suitable for a wide range of grains including rice, wheat, corn, barley, and more.

- Improved Efficiency: Enhances the efficiency of subsequent processing steps by providing cleaner grain.

- Cost-Effective: Reduces the need for multiple cleaning stages, saving time and operational costs.

Rice Sifter Machine

Product Description:

After polishing, the white rice is separated into head rice and, large and small broken rice by a sifter. Head rice is normally classified as kernels, which are 75-80% or more of a whole kernel. The sifter is made up of a series of oscillating screens through which the rice passes. The output from the bottom screen is the very fine broken tips and is called the “brewers”.

Advantages:

- Designed with sophisticated multi-stage separation system.

- Designed with easily removable tray system.

- Equipped with rubber bouncing balls to prevent clogging of screens.

- Suitable 2 hp 1.5kW x 1440 rpm Electric Motor.

Silky Polisher Machine

Water Jet (Silky) Polisher machine polishes the rice surface by spraying water through the mixing chamber and creating friction among the rice grains using milling rollers. Using water gives the output grain a shiny surface, thus the name “silky” polisher. Grains are coated with a fine spray of water and is subjected to gelatinization in the polishing chamber, resulting in a high degree of glazing.

The weight-controlled outlet of the polisher controls the retaining time of kernels inside the milling chamber. Easy maintenance is facilitated by features such as motor placement outside the equipment body. Stability is increased with a lower height.

The machine is specifically designed and best suited for raw rice, steam rice and boiled rice. The unique design of the water dosing mechanism eliminates the need for compressed air. The moisture injection system ensures that the injection occurs only when the rice is in the chamber. Specially designed CAM rollers ensure higher glazing with minimum damage.

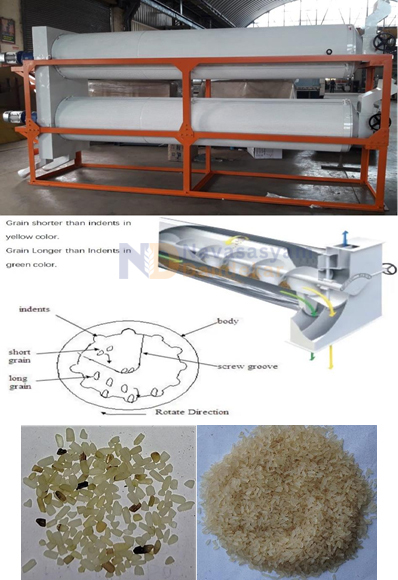

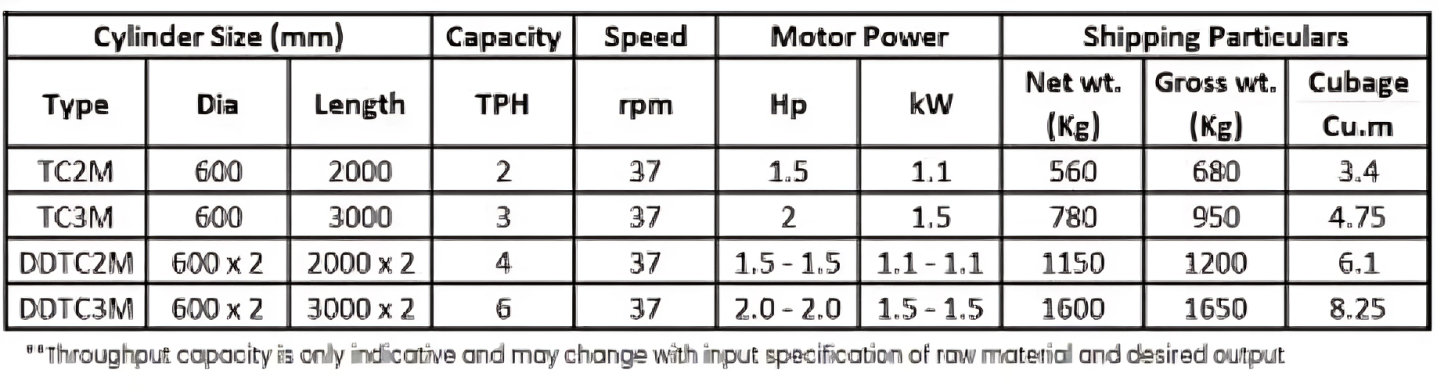

Trieur Cylinder / Length Grader

Application:

Rice The indented cylinder grader, also known as TRIEUR CYLINDER, is used for separation of broken rice from whole rice. It is also used in Flour Mills for separating weed seeds (cockles) and broken from wheat. The cylinder grader achieves separation on the basis of variations in length as distinct from sieve type grader which achieves separation by thickness.

The machine consists of horizontal cylinder made up of special sheets segments into which thousands of precise indents or pockets are formed. Cylinder rotates slowly and spreader provided spreads the grain equally.

The brokens being smaller in length are caught in pocket and as the cylinder rotates they are lifted up to a certain point after which they drop out into a central collecting trough. The degree of separation is determined by the position of the collecting trough. Its position is so adjusted as to collect the maximum brokens with negligible whole rice.

Advantages and Features:

- Perfect separation of whole rice & broken.

- More separation efficiency.

- Grading in uniform broken depends on using multiple cylinder of different cylinder sheet.

- Separation of broken adjustable deepening on final product quality to 100% separation.

- Different size of Indented Cylinder suitable to rice.

- Ease of maintenance.

- Automatic brush cleaning device provided for cleaning of indent pockets.

- Low power consumption.