Transforming Processing into Profit (A Blend of Science, Innovation, and Expertise)

Introduction

"With a deep understanding of the science behind pulse processing, we combine years of experience, a vast knowledge bank, and cutting-edge technology to design processes that deliver unmatched results. Our goal is to maximize yield, productivity, and resource / process optimization while reducing processing costs."

Key Aspects

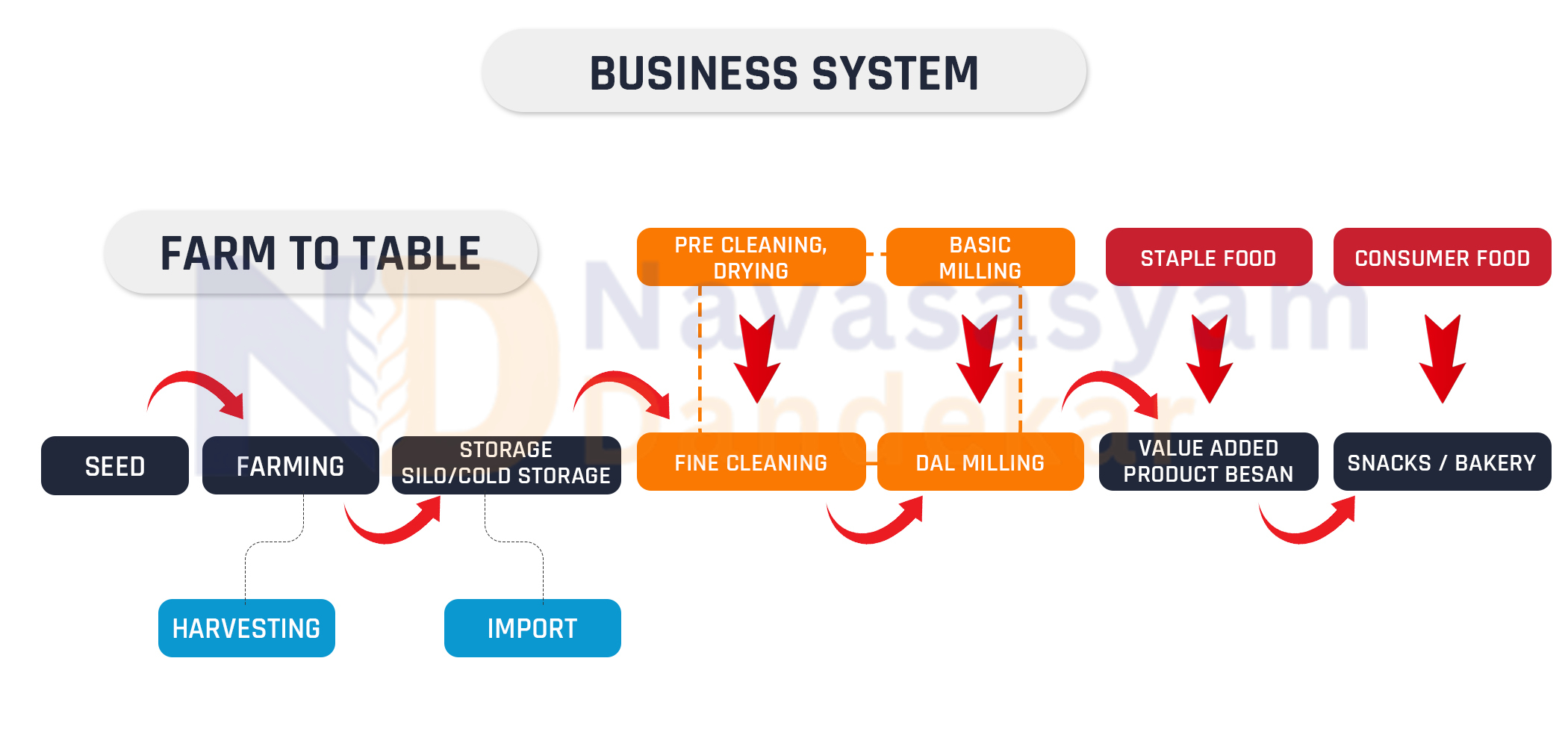

- Development of Customised flowcharts/Process diagram to suit customers requirement.

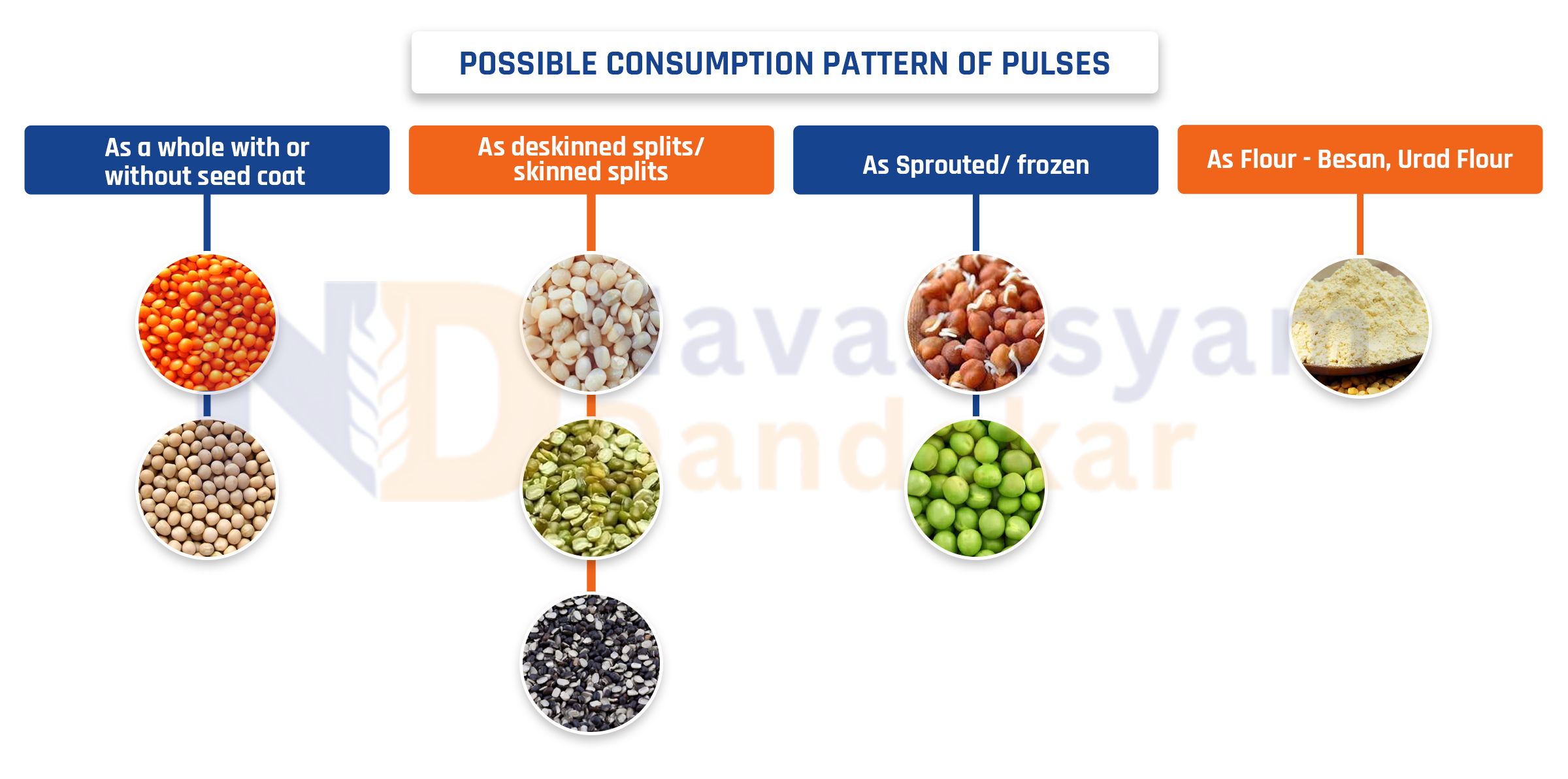

- Process innovation to suit different types of pulses and end-product requirements.

- Seamless integration of new processes into existing or new setups (Greenfield and Brownfield projects).

"Leveraging our vast knowledge bank and real-world data, we develop and innovate machines that enhance the processing experience."

Examples

"Our automated oil dosing machine is widely acclaimed by millers for its ability to reduce oil consumption while significantly enhancing de-skinning efficiency"

Our unique oil and water dosing system atomizes flow into tiny particles, ensuring deeper penetration between the seed coat and cotyledon. This enhances de-skinning efficiency while reducing oil and water consumption, leading to cost savings and fewer sorter rejects.

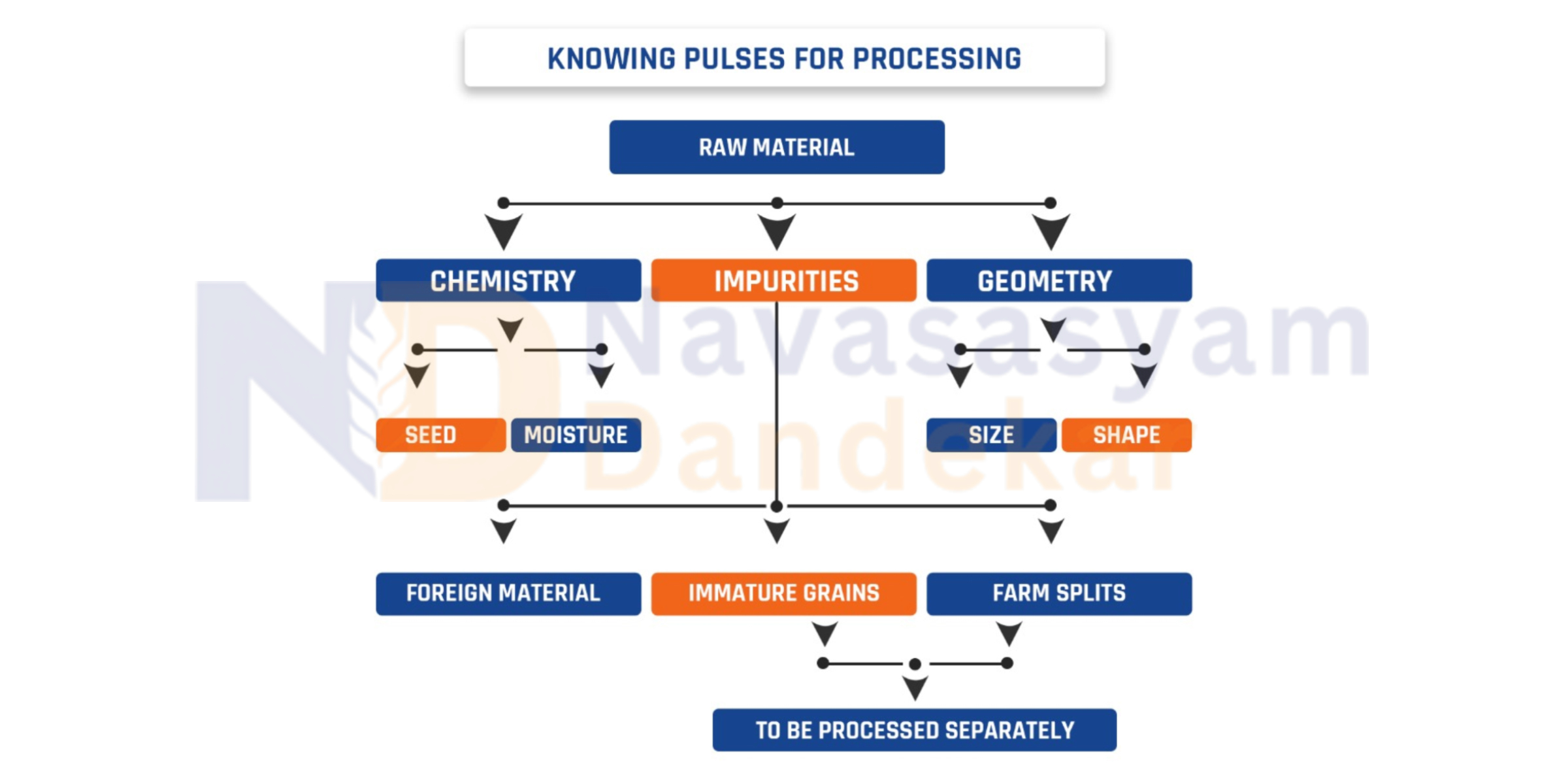

Scientific Approach to Processing

"Our approach is rooted in understanding the critical variables of pulse processing, such as tempering time, drying temperatures, and moisture control based on end use"

Highlights

- Tempering Techniques: Optimized resting times to improve de-skinning and minimize splits.

- Drying Expertise: Scientific control of drying temperatures to preserve quality, enzyme activity and maximize yield.

- Moisture Management: Ensuring consistent results while processing.

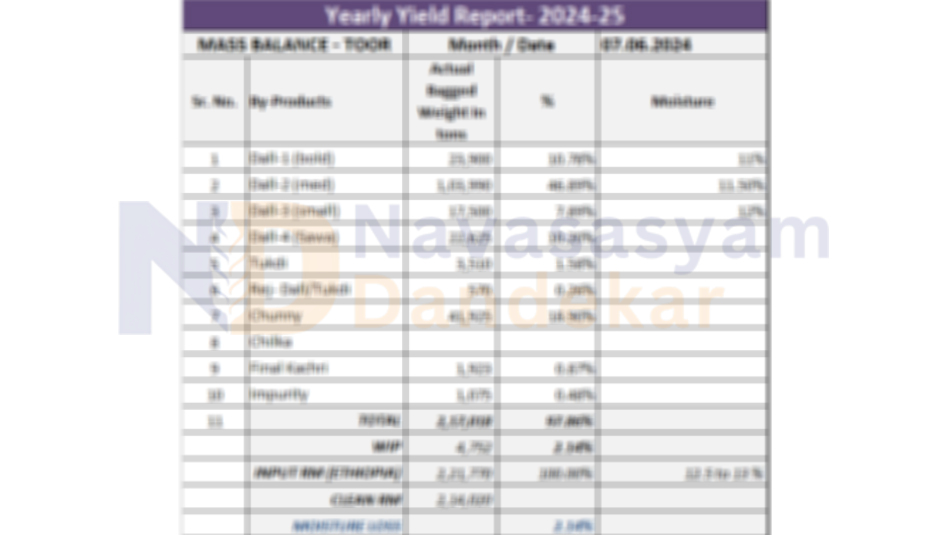

Yield and Cost Optimization

"Our ultimate aim is to help our customers achieve higher yields and lower operational costs while maintaining superior product quality."

Scientific and Data-Driven Approach

"Our vast repository of data and expertise enables us to analyze and improve every step of the pulse processing journey."

- Data-backed decisions for process improvements.

- Incorporation of customer-specific insights for tailored solutions.

Results That Speak for Themselves

#Conditions Apply

Yield and Productivity Gains

Example: Our innovative processing methods, guided by a precise flowchart, have enabled the production of 17 flasks of urad batter, surpassing the typical 15.5 flasks. Additionally, our advanced machine design ensures optimal split control during the production of urad gota and masoor gota (football).

Cost and Resource Efficiency

Automation and engineering form the backbone of our solutions, enabling significant reductions in variable costs while enhancing productivity.

The NDPL Advantage: Expertise in Action

A. Unique Problem-Solving Skills

- "We excel in solving complex processing challenges with innovative and practical solutions."

- End-to-End Support

- From feasibility studies to after-sales support, we guide customers through every step of the journey.

Real-World Experience

"Our knowledge bank is built on years of hands-on experience across diverse projects and processing challenges."

Miller Services

Miller Services: Expertise for Optimum Results

We understand the importance of skilled operations in ensuring optimal machine performance and consistent quality. To support our customers, NDPL offers trained miller services, bringing expertise right to your doorstep.

Our trained millers' services are designed to help you achieve the best results from your plant. With in-depth knowledge of pulse processing and extensive hands-on experience, our millers ensure:

- Optimal Plant Setup: Tailored adjustments for maximum efficiency and productivity.

- Enhanced Capabilities: Fine-tuned processes that bring out the full potential of your plant.

- Consistent Quality: Precise calibration of machines for superior product quality.

- Reduced Downtime: Proactive maintenance and troubleshooting for uninterrupted operations

Partner with us to experience the perfect combination of science, technology, and expertise. Let us help you optimize your plant for better yield, quality, and efficiency."

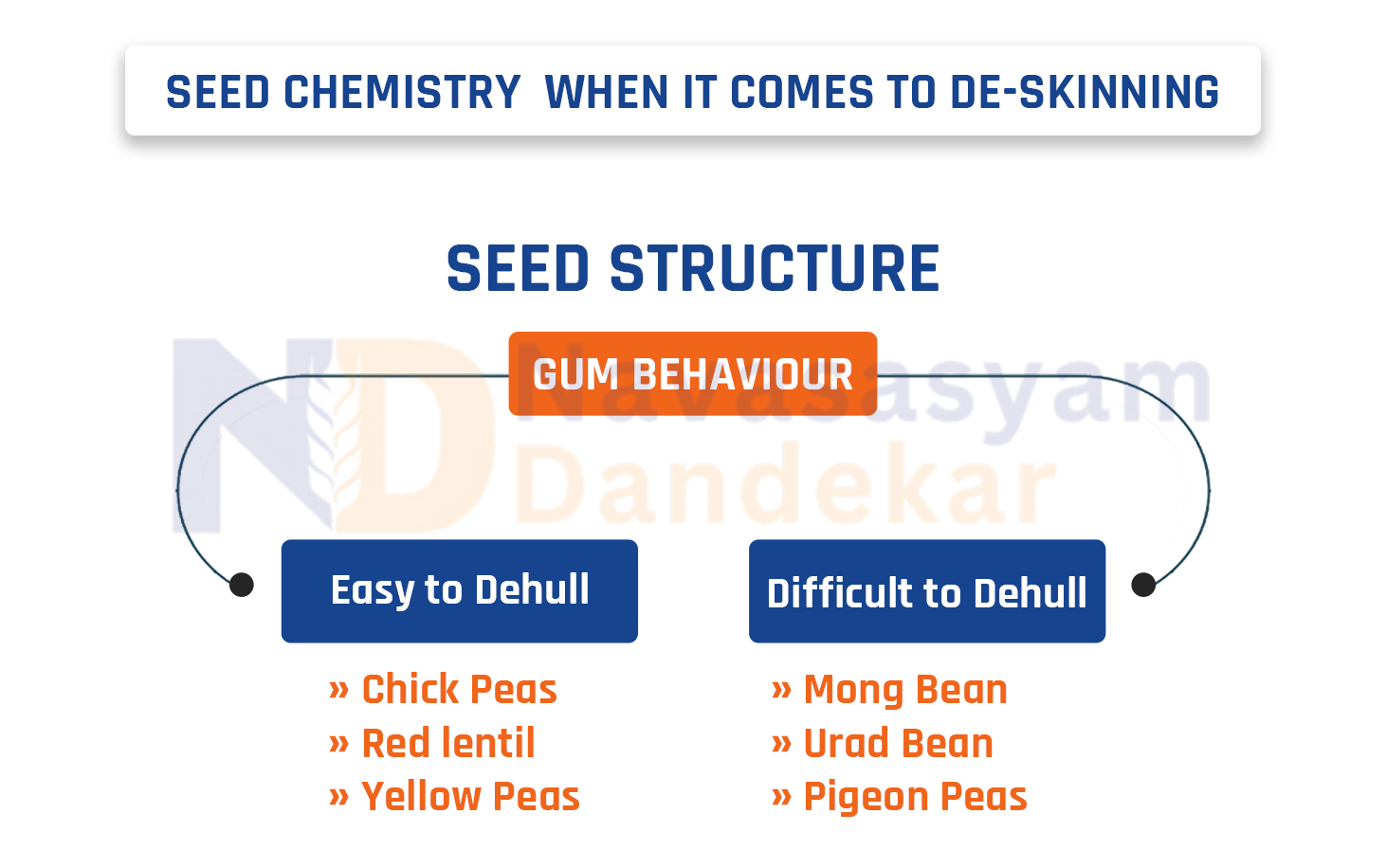

Seed Chemistry When it Comes to De-skinning

Anatomical Part & Proportion Pulses That Are Milled

Proportion Range of whole grain (%) (#Conditions Apply)

| Pulses | Seed coat % | Cotyledon % | Germ % |

|---|---|---|---|

| Chickpeas | 12-13 | 85.5 - 86 | 1.5-2 |

| Pigeon peas | 15 - 16 | 82 – 83.5 | 1.5-2 |

| Mung beans | 12 - 13 | 86 - 87.5 | 1–1.5 |

| Black gram | 12.5–13.5 | 86-87 | 1- 1.5 |

| Lentils | 8-9 | 89-90 | 1.5–2.1 |

| Yellow Peas | 7.5 -9 | 90-91 | 1.5–2 |